Safety

Installation and Safety Information

Safety Considerations

Laser Safety

The Center for Devices and Radiological Health (CDRH) was established in October, 1982, by the U.S. Food and Drug Administration (FDA) to protect the public health in the fields of medical devices and radiological health.

Manufacturers of products subject to performance standards under the Radiation Control for Health and Safety Act of 1968 are required to furnish various reports to the CDRH.

The Pearl Imager is certified as a Class I laser product. This means that hazardous laser radiation is not emitted outside the instrument. Radiation emitted inside the Pearl Imager is confined within protective housings and external covers. A series of safety interlocks ensures that the laser beam cannot escape during any phase of user operation.

Two lasers emit at 785 nm and the other two at 685 nm. The 785nm lasers have a peak power rating of 1 watt. The 685nm lasers have a peak power rating of 0.5 watt. The 685 nm laser emits visible laser radiation - direct exposure to either beam may cause eye damage. Laser radiation from each laser uniformly illuminates the target area, which is the imaging

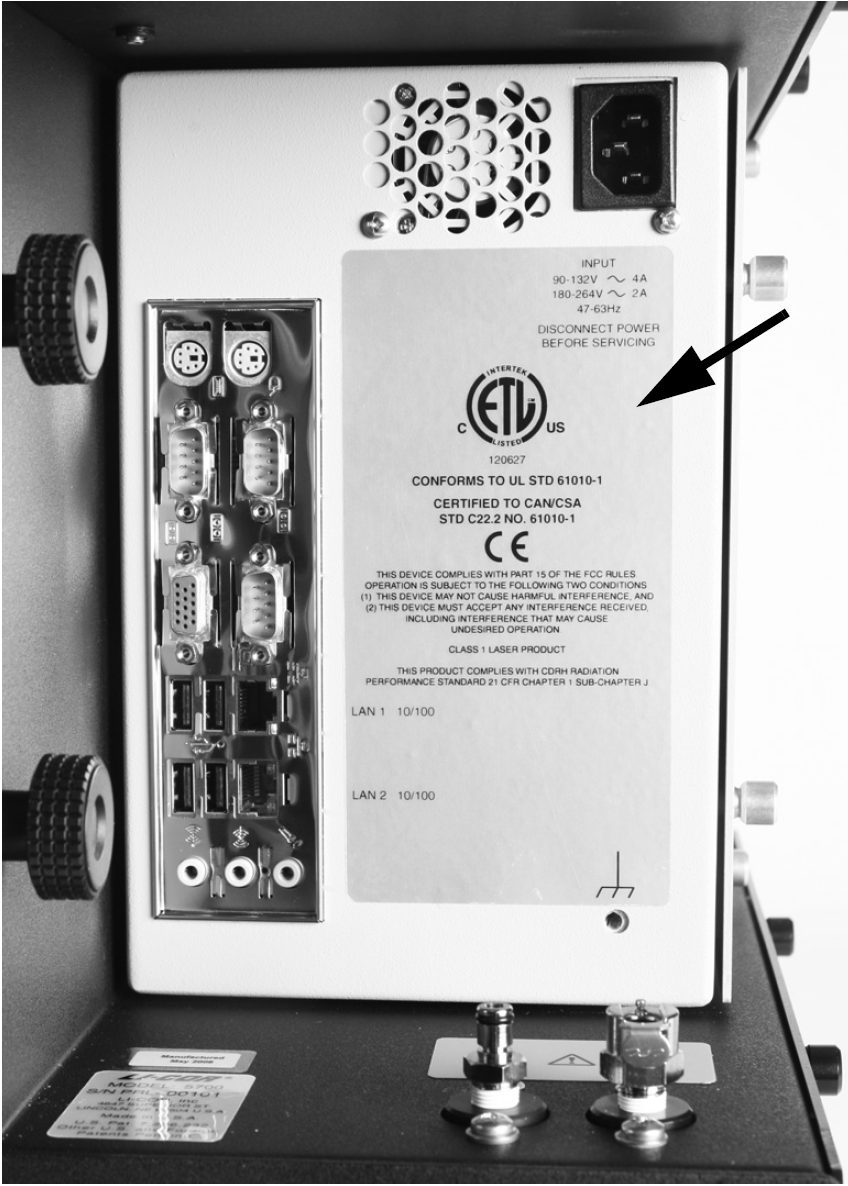

The CDRH implemented regulations for laser products on August 1, 1976 (CDRH radiation performance standard 21, Code of Federal Regulations Chapter 1, Sub-chapter J). Compliance for products marketed in the United States is mandatory. This product complies with CDRH radiation performance standard 21 CFR Chapter 1, Sub-chapter J. Ce produit est conforme à la performance de rayonnement CDRH chapitre CFR norme 1 Sous-chapitre J. The label that must be attached to laser products marketed in the United States is Figure 84 and is located on the rear panel of the Pearl (Figure 85), indicating compliance with CDRH regulations.

WARNING: Use of controls or adjustments or performance of procedures other than those specified herein may result in hazardous radiation exposure.

AVERTISSEMENT: L'utilisation des commandes ou le réglage ou la performance des procédures autrement qu'il a été indiqué dams le présent texte peut résulter en de dangereuses expositions aux radiations.

|

Safety Interlocks

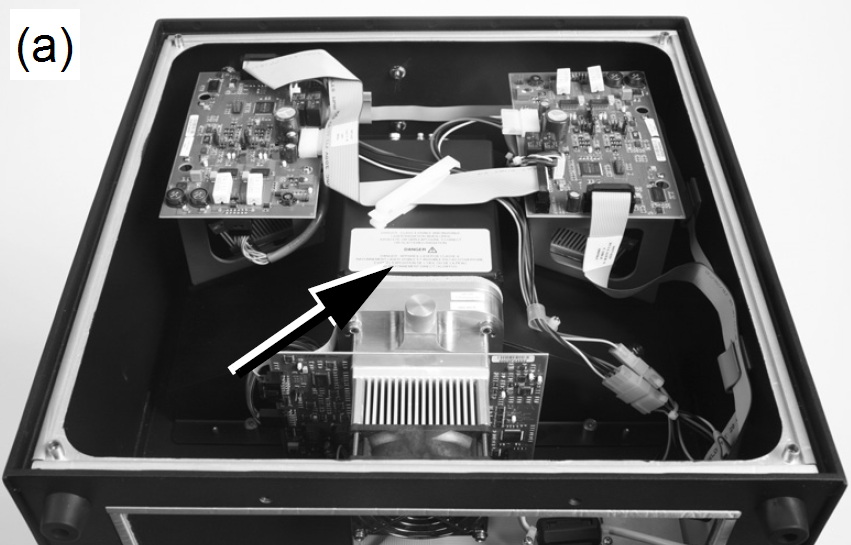

Where there is a potential for class 4 laser radiation behind a given panel, the label in Figure 86 is affixed to the panel. The label shown in Figure 86 is affixed to the Pearl Imager in two locations; one on the rear lower access panel and one on top of the camera hood (Figure 87).

The Pearl Imager has two safety interlocks that prevent exposure to laser radiation when the Pearl imaging drawer is opened during operation. Do not attempt to defeat these interlocks. The drawer interlocks are located in the back of the instrument behind the rear lower access panel, which is also protected by interlocks. This second set of interlocks prevents exposure to laser radiation if the rear lower access panel is removed during operation. These interlocks are also located behind this back access panel (Figure 88). Do not attempt to defeat these interlocks (Figure 89).

Placement in the Laboratory

The Pearl Imaging System weighs approximately 25 kg (55 lb). The instrument should be placed on a laboratory bench that is level and sufficiently sturdy to bear the instrument's weight. The bench should also be able to bear the weight of the computer if the computer is to be installed beside the Pearl Imaging System instrument.

The Pearl Imaging System is intended for indoor use only.

Ambient Laboratory Conditions

Place the Pearl Imaging System away from external heat sources (furnaces, windows, etc.). Additional heating can cause high temperatures within the enclosure. The heater plate in the Pearl Imaging System imaging bed cannot cool the imaging bed if ambient temperature is above the set point for the imaging bed heater plate.

Place the instrument away from sinks or other sources of water that pose a shock hazard. Recommended operating conditions are 15-35 °C and a dew point not greater than 22 °C to prevent condensation on the laser assemblies, which are cooled during operation.

Instrument Ventilation

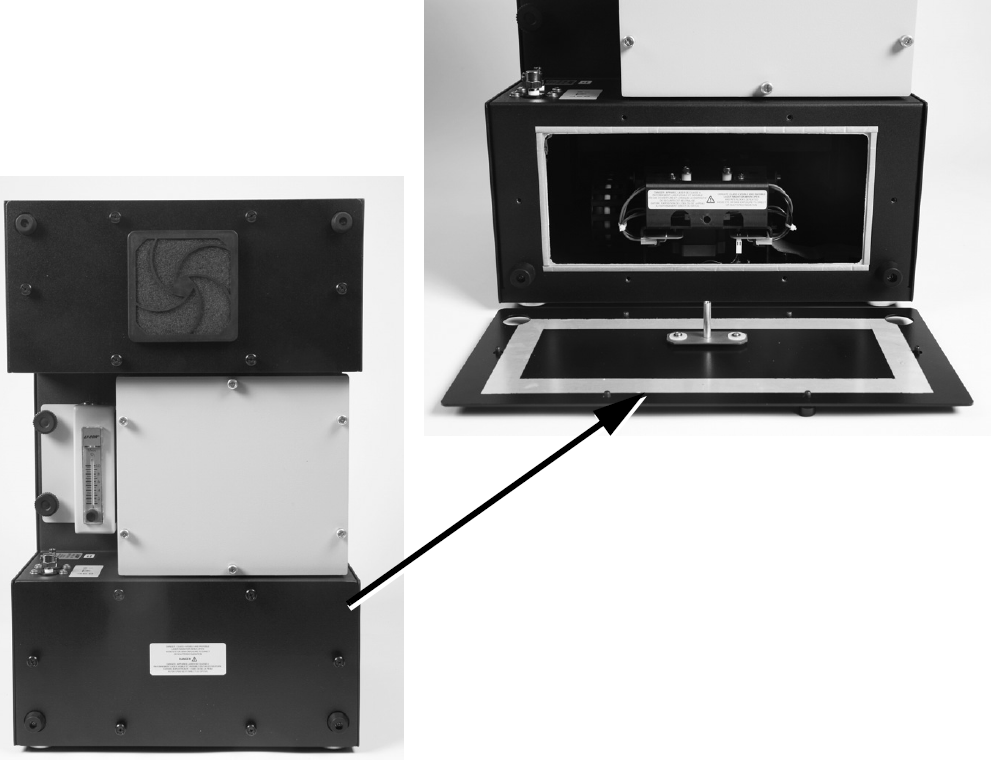

The air intake fan on the back of the Pearl® Imaging System (Figure 102. ) is used to cool the internal electronics and maintain fresh air circulation throughout the internal volume of the instrument. Fresh air circulation prevents an internal buildup of anesthesia gas or oxygen. The air intake is filtered and the filter should be periodically cleaned (Routine Maintenance and Cleaning). Make sure there is plenty of room behind the instrument (Figure 103. ) so that the air intake is not blocked and the filter is easily accessible for cleaning.

Room Ventilation

A room with a minimum of 15 air changes per hour (non-recirculating) is required when using isoflurane anesthesia gas.

Space Requirements

The Pearl Imaging System instrument requires an area approximately 41 cm W (16") x 41 cm D (16") x 66 cm H (26"). Depth with the imaging drawer open is 63.5 cm (25”).

Level the Imager

Level the instrument to prevent the imaging drawer from scraping the lab bench or table in front of the instrument and to keep the instrument from tilting.

The instrument can be leveled by turning the threaded metal inserts located in each of the 4 plastic feet (Figure 90).

|

Moving the Imager

LI‑COR recommends that you do not move your imager. Instead, please contact LI‑COR Technical Support for options.

LI‑COR cannot be held responsible for any damage incurred while moving, transporting, or shipping the

Anesthesia Safety Considerations

WARNING: Isoflurane gas is a human inhalation hazard that needs to be ventilated away from workers. It can cause coughing, sore throat, dizziness, drowsiness, headache, and unconsciousness. Pregnant women should not work in an environment where there is any potential isoflurane risk.

AVERTISSEMENT:

Le gaz isoflurane est un danger pour le système respiratoire humain et il doit être dispersé par ventilation loin des ouvriers. Il peut provoquer la toux, la gorge endolorie, le vertige, la somnolence, le mal de tête, et l'inconscience. Les femmes enceintes ne devraient pas travailler dans un environnement où il existe un danger d'inhalation d'isoflurane.

Oxygen Safety Considerations

Oxygen gas is a colorless, odorless, oxidizing gas. If O2 is used as a carrying gas for the anesthesia gas, the chief physical hazard associated with the release of oxygen is its oxidizing power, which can greatly accelerate the burning rate for combustible materials. Keep the room well ventilated with fresh air by observing the room ventilation recommendations above.

Chemical Safety

LI‑COR Biosciences recommends that all biochemicals be handled carefully, and that safe laboratory procedures be followed at all times. Be aware of the hazards associated with any chemical before you begin work.

The LI‑COR® Pearl Imaging System should not be used with any radioactive materials.

Use of DMSO and Other Strong Solvents

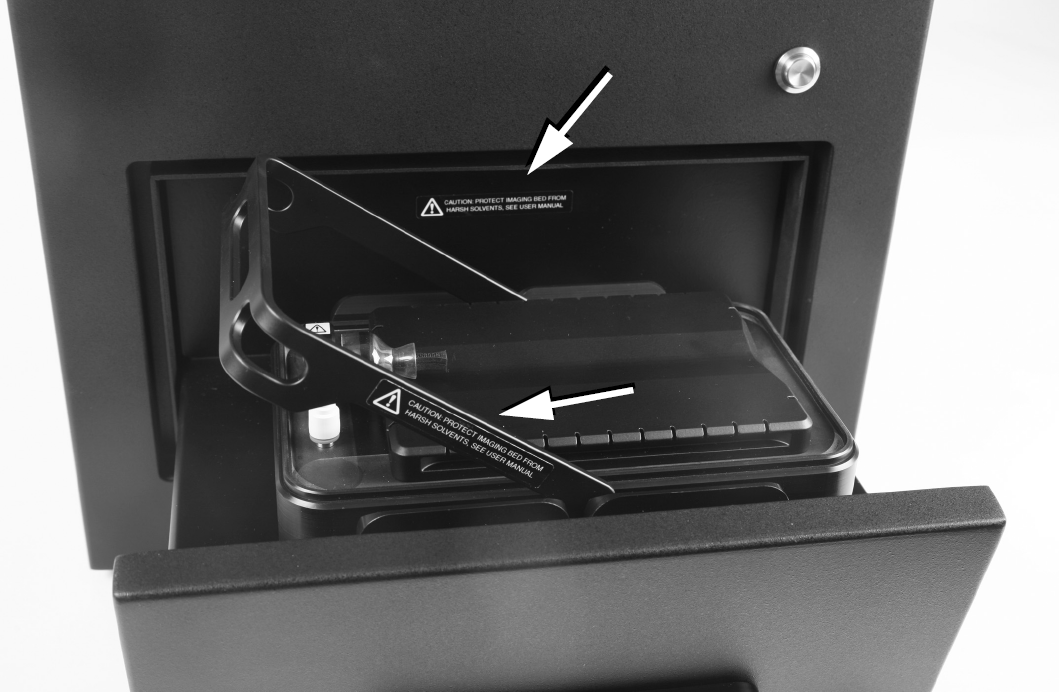

CAUTION: Strong solvents, including DMSO, will permanently discolor the imaging

ATTENTION:

Les dissolvants forts, y compris DMSO, décoloreront de manière permanente la surface du lit d'image. Évitez tout contact. En outre, tous les produits d'IRDye dans DMSO incorporeront à la surface du lit et seront évidents dans les images.

Whenever possible, inject the animal on a separate surgical bed and clean off any exterior dye product on the animal before transferring the animal onto the Pearl Imaging System imaging bed. In the event that the imaging bed becomes contaminated with dye, wipe with Nair® hair remover and thoroughly clean and dry before use.

Electrical Considerations

Power Cords and Disconnecting Power

The Pearl® Imaging System is equipped with a 3-wire grounding-type plug. This plug will only fit into a grounding-type outlet. This is a necessary safety feature. If you are unable to insert the plug into the outlet, you will need to replace the outlet. Do not defeat the purpose of the grounding-type plug.

Do not locate the Pearl Imaging System where the power cord will be walked on or exposed to water or chemical spills.

The Pearl Imaging System draws a maximum of 4 amperes at 120V (see Odyssey® F Imager Specifications). If an extension cord is used, make sure the total of the ampere ratings on the instruments plugged into the extension cord does not exceed the extension cord ampere rating. Also make sure the total amperage of instruments plugged into the wall outlet does not exceed the amperage capacity for the outlet (usually 15 or 20 amperes in the United States).

Disconnect power before maintenance or servicing.

Débrancher le pouvoir avant d'entretenir.

See Figure 84. for the location of these statements on the product's regulation compliance label.

Fuse Replacement

There are no user replaceable fuses in this instrument.