Air Pumps and Accessories for the LI-830, LI-850, and LI-7000

The sample cells of the LI-830, LI-850, and LI-7000 gas analyzers must be continually flushed while making measurements. The system time constant (T), a measure of how quickly the system responds, is determined by the cell volume and flow rate through the cells:

1‑1

The list of parts on the next page can be used to make a simple air flow system to move sample air streams through these analyzers. Parts available for sale through LI-COR are listed, as well as alternative vendors. Note the following precautions when designing your air flow system:

- Always install an external air filter into the sample air stream before it enters the analyzer. Failure to do this will lead to contamination of the optical path.

- Pressures of 15 kPa or more above ambient can cause damage to the source and detector windows. The safest mode of operation is to pull air through the optical bench.

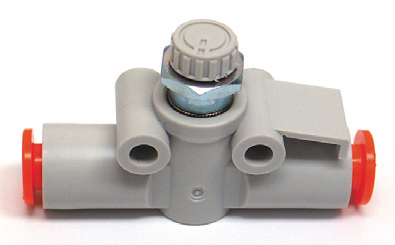

- Devices such as valve-actuated rotameters and regulator valves can be used to reduce flow rates.

The LI-830 and LI-850 analyzers are available with a built-in pump. If you want to add the pump as a retrofit option, we offer 800-910 pump kit, which provides flow control and diagnostics integrated with the gas analyzer. The pump installs in the analyzer case, and it is powered through the analyzer power supply. It provides a fixed flow rate of 0.75 liters per minute (lpm). If your instrument is not equipped with the built-in pump, you can use any pump with a maximum flow rate of 1.0 lpm.

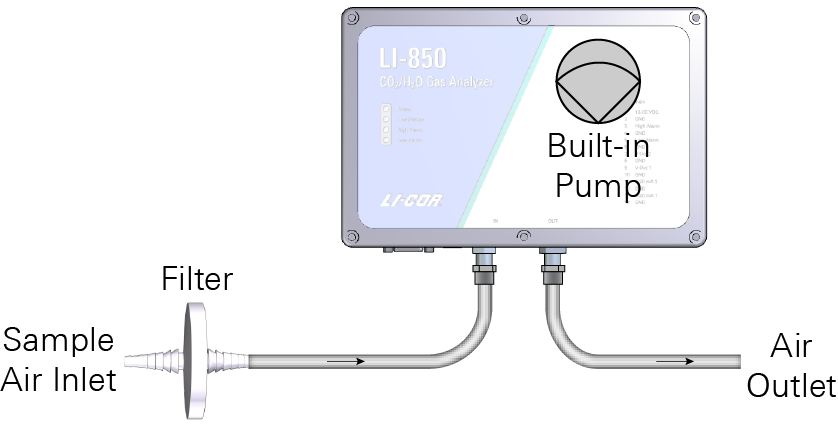

Example #1: Built-in Internal Pump

The internal pump is positioned downstream of the optical bench and thus, it provides negative pressure on the system. There is no need to use a regulator, exhaust vent, or flow meter in this configuration.

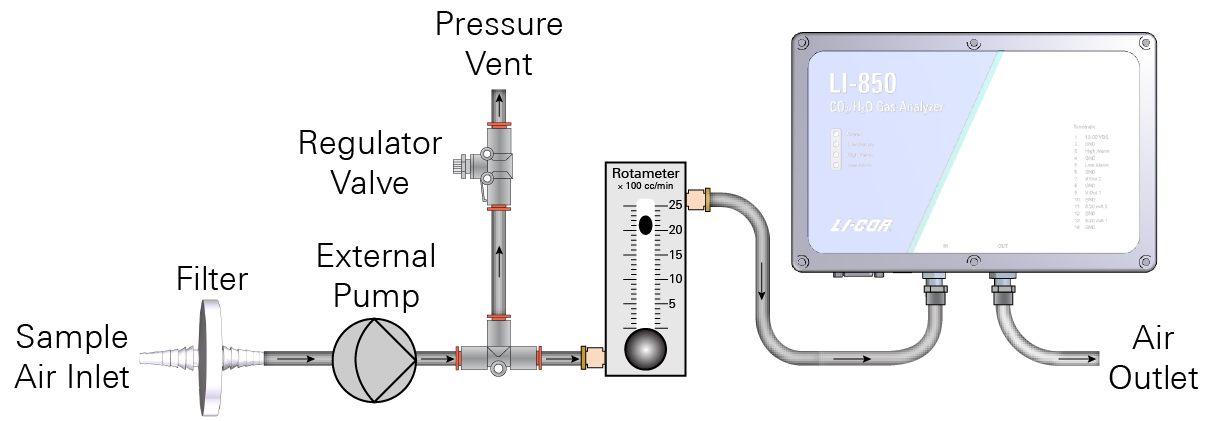

Example #2: External Pump with Positive Pressure

An external pump upstream of the analyzer is ideal when dealing with large volumes of incoming air. This configuration is less prone to leaks because it uses positive pressure. Be careful with very humid air, because the positive pressure can cause water droplets to form.

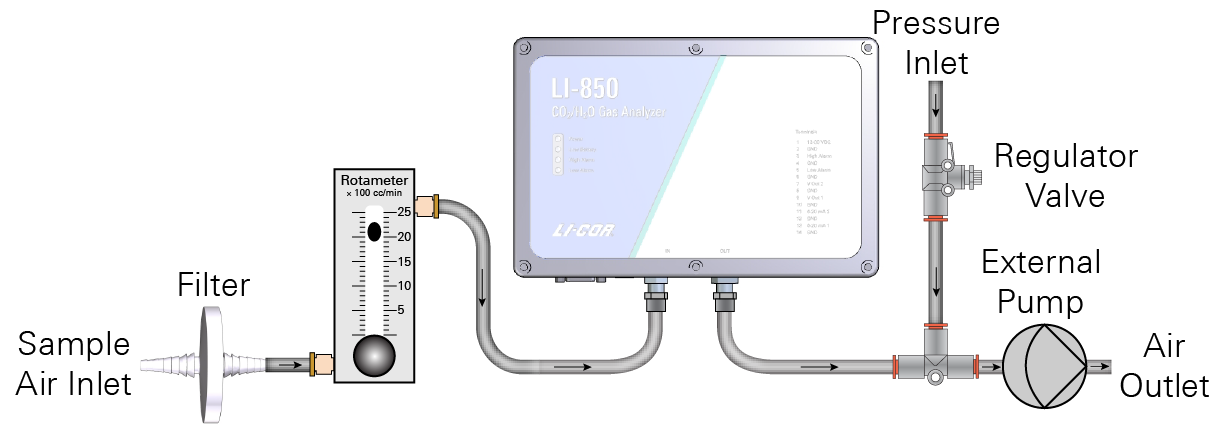

Example #3: External Pump with Negative Pressure

An external pump downstream of the analyzer is ideal for injection measurements and small-volume measurements. This configuration is more susceptible to the effects of a leak because it uses negative pressure, but it eliminates the risk of excessively pressurizing the optical cell.

Flow Rates

| Model | Min. Flow (lpm) | Max. Flow (lpm) |

|---|---|---|

| LI-830 and LI-850 | 0.25 | 1 |

| LI-7000 | 0.25 | ~50 |

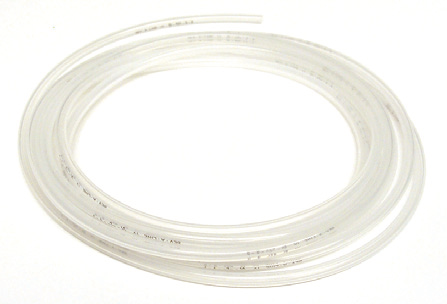

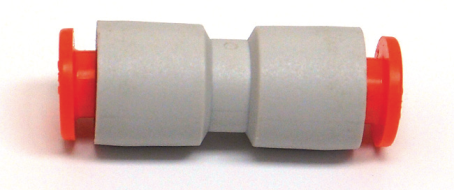

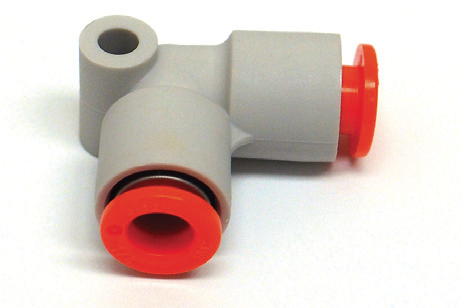

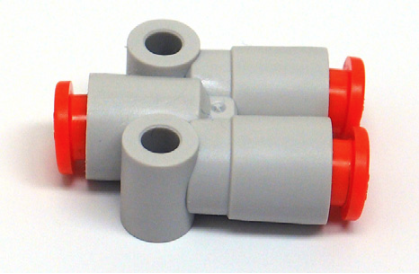

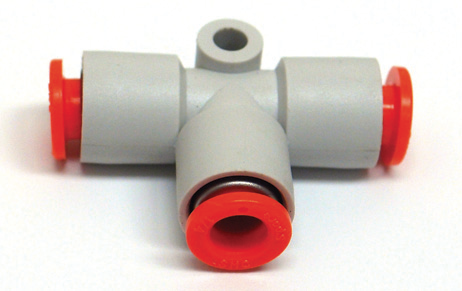

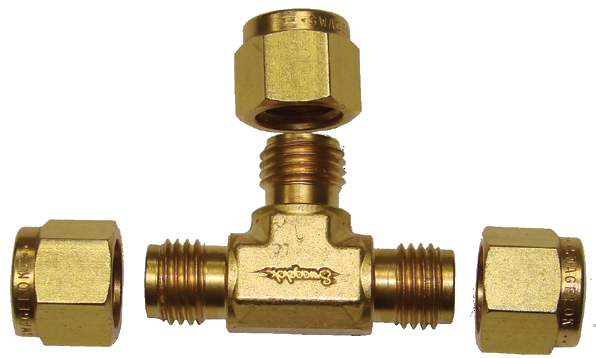

Plumbing accessories, filters, and scrub tubes available from LI-COR

Other Suppliers

- Coast Pneumatics: http://www.coastpneumatics.net

- Parker: http://www.parker.com

- Swagelok: http://www.swagelok.com

Contact LI-COR if you have questions regarding your instrument or about how to assemble an air flow system.