Troubleshooting

If the analyzer is not functioning properly, check for the following common problems first:

- Are all cables connected correctly?

- Check the data cables to be sure they are connected. Check component power cables, if applicable.

- Are there any gas and/or liquid leaks?

- Inspect tubing junctions and filters for any indications of a leak or damage.

Power supply problems

- Suitable power supply?

- Be sure the local power is compatible with all components in the system (120 to 240 VAC; 60 or 50 Hz).

- Power cable connected?

- Check the power supply cord to ensure it is connected properly.

- Fuses in place and not open?

- Check the fuses and replace any fuses that are open. If the DIC module main power switch works but the gas LI-850 does not get power when switched on, check the fuse.

- Does the instrument power supply setting match the supply outlet voltage?

- If the voltage supplied to the instrument is greater than the selected value on the power cord switch, the analyzer could be damaged.

Computer not communicating with gas analyzer or DIC module

If the program does not connect to the components, check the cables and configuration.

- Incompatible cable or adapter?

- Be sure to use the RS-485-to-USB cable, RS-232-to-USB, or network cable provided with your device. Other brands may provide inconsistent performance.

- Correct IP address (LI-5300A with LI-7815 only)?

- Check that the correct IP address has been entered in the DIC program. The IP address of the LI-7815 may have changed without notice. Check that the Ethernet cable is connected to both LI-7815 and the computer. The program cannot connect to LI-7815 wirelessly — the wired connection is required.

- Correct COM port settings?

- To find the serial port number, open the Device Manager (press the Windows key

, type Device Manager, then press Enter). Click Ports (COM & LPT). Look for USB Serial Port (COM#). The serial port numbers are shown beside the ports.

, type Device Manager, then press Enter). Click Ports (COM & LPT). Look for USB Serial Port (COM#). The serial port numbers are shown beside the ports. - Computer needs a fresh restart?

- An occasional reboot can resolve a variety of mysterious PC issues. A fresh start every morning helps keep them from ever appearing.

- Gas analyzer disconnects spontaneously.

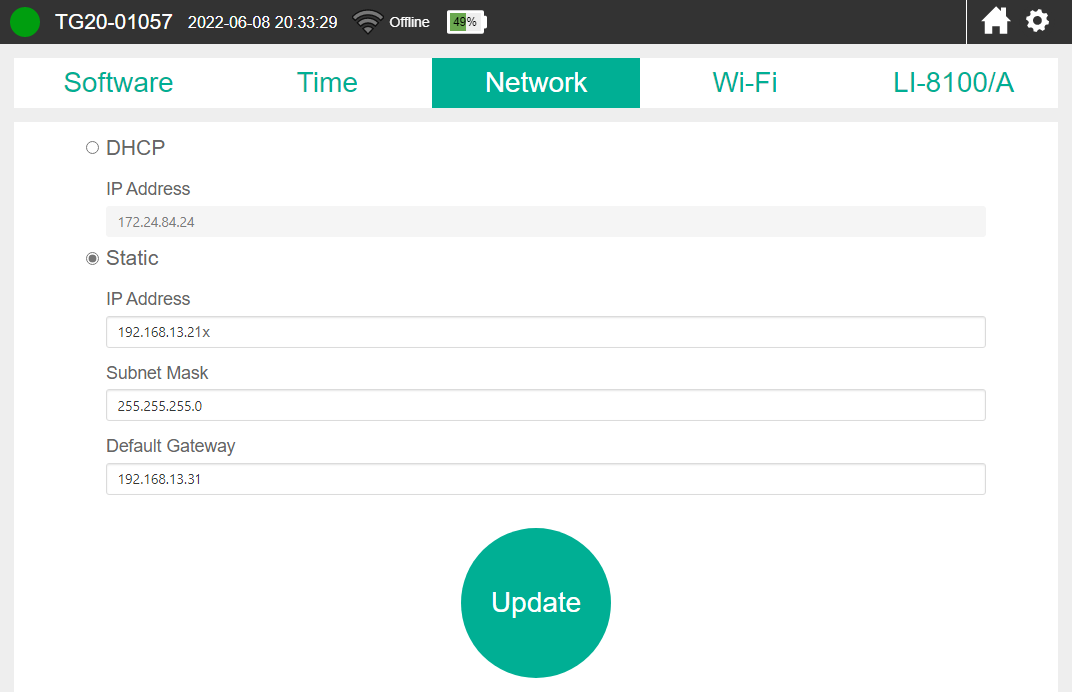

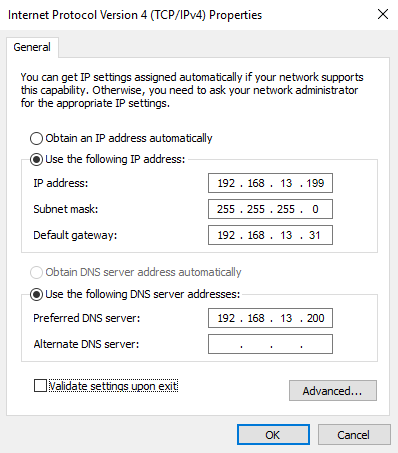

- If you experience persistent connection issues between the computer and LI-7815, change the IP address settings of the gas analyzer and computer from dynamic to static and enter compatible IP addresses for both devices. For the gas analyzer, open the web interface in a browser. Go to Settings > Network and select Static. Enter an IP address such as 192.168.13.210.

For the computer, enter an IP address such as 192.168.13.199 following these steps:

-

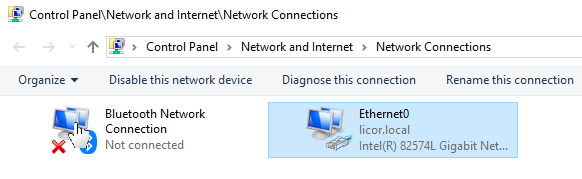

Open the network settings on your computer.

Press the Windows key (

), type Network Connections into the search bar and press Enter to view network connections.

), type Network Connections into the search bar and press Enter to view network connections. - Double-click the internet connection to bring up the Local Area Connection Status, then click Properties.

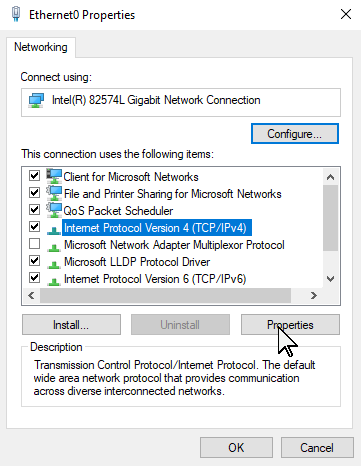

- Select Internet Protocol Version 4 (TCP/IPv4), then click Properties.

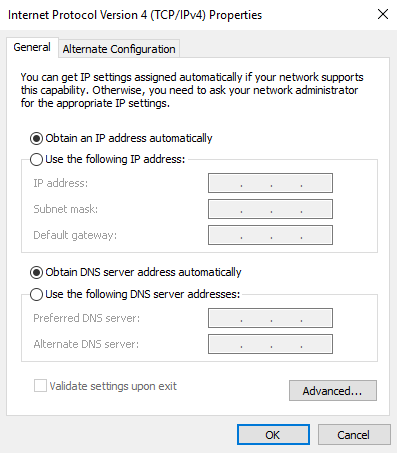

- If you need a dynamic IP address, select Obtain an IP address automatically and Obtain DNS server address automatically. If you need a static IP address, select Use the following IP address and enter the IP address and Subnet mask.

| Dynamic IP Address | Static IP Address (Recommended) |

|---|---|

|

|

Cooling system problems

- Room too hot?

- Make sure the ambient room temperature is not too high.

- Cooling fan working?

- Check the cooling fans to see if they are blocked by foreign objects or dust.

Measurement stability problems

If issues are indicated by poor measurements and stability, the following solutions may help.

Data unexpectedly variable or unstable

-

Leak near the syringe or tubing?

-

You may see air bubbles enter the liquid or liquid escaping the syringe, indicating a leak. Tighten the syringe onto the rotary valve using your fingers. Also check the tube junctions and tighten any loose connections.

Carrier gas flow rate not stable

- Adequate air supply pressure?

- Confirm that the pressure is 16 to 18 psi (110 to 124 kPa). If the pressure is too low, it will not maintain a constant gas flow rate during the measurement. If the pressure is set too high, it will burst connections within the system.

- Is the pressure regulator valve open enough?

- On the tank of compressed gas, be sure the regulator valve is open enough to supply the flow rate from 200 to 350 mL/min.

- If using compressed air, is the pressure high enough?

- The pressure of compressed air should be stable with no fluctuation.

Solution problems

- Solution not loaded or loading with issues?

- Check that the reagent/acid tubing is immersed into the solution and that no air bubbles are trapped inside the tubing.

- Inconsistent measurement performance?

- Ensure that the sample solution is homogeneous. Mix the sample thoroughly or stir it if obvious separation is visible.

- Components get contaminated?

- Samples with suspended particulates should be avoided since they may block the tubing.

Gas path problems

Always check for leaks using the software program after any component along the gas path is reconnected or changed.

- Filter clogged?

- Change the external filter and the two pieces of the tubes on the back of the analyzer if needed.

- Tubing clogged or damaged?

- Inspect tubing for clogs or obstructions. Replace any tubing that is damaged for blocked, if needed.

- Internal contamination?

- The stainless steel condensing module needs to be cleaned. See Support: LI-53x0A Dissolved Inorganic Carbon Analyzers.

LI-7815 CO2/H2O Trace Gas Analyzer problems

Refer to the LI-7815 CO2/H2O Analyzer instruction manual.

LI-850 CO2/H2O Gas Analyzer problems

Refer to the LI-850 CO2/H2O Analyzer instruction manual.