Installing the LI-190R Quantum Sensor in Biomet Systems

Printable PDF: Installing the LI-190R Quantum Sensor in Biomet Systems

(Installing-LI-190R-12676.pdf)

Download this content as a pdf that can be saved to your computer or printed.

The LI-190R quantum sensor (part number 7900-190) measures photosynthetically active radiation (PAR). Here we provide basic installation and operation instructions for using the LI-190R in a LI-COR biomet data acquisition system.

| LI-190R Specifications: | |

|---|---|

| Spectral response: | 400 to 700 nm |

| Energy range: | 0 to 2000 µmol/m2/s |

| Absolute calibration: | ±5% |

| Output signal: | 0 to 20 µA |

| Linearity: | Maximum deviation of 1% up to 10,000 μmol s-1 m-2 |

| Cosine correction: | Up to 80° angle of incidence |

| Azimuth error: | <1% over 360° at a 45° elevation angle |

| Cable lengths: | 5 and 50 meters |

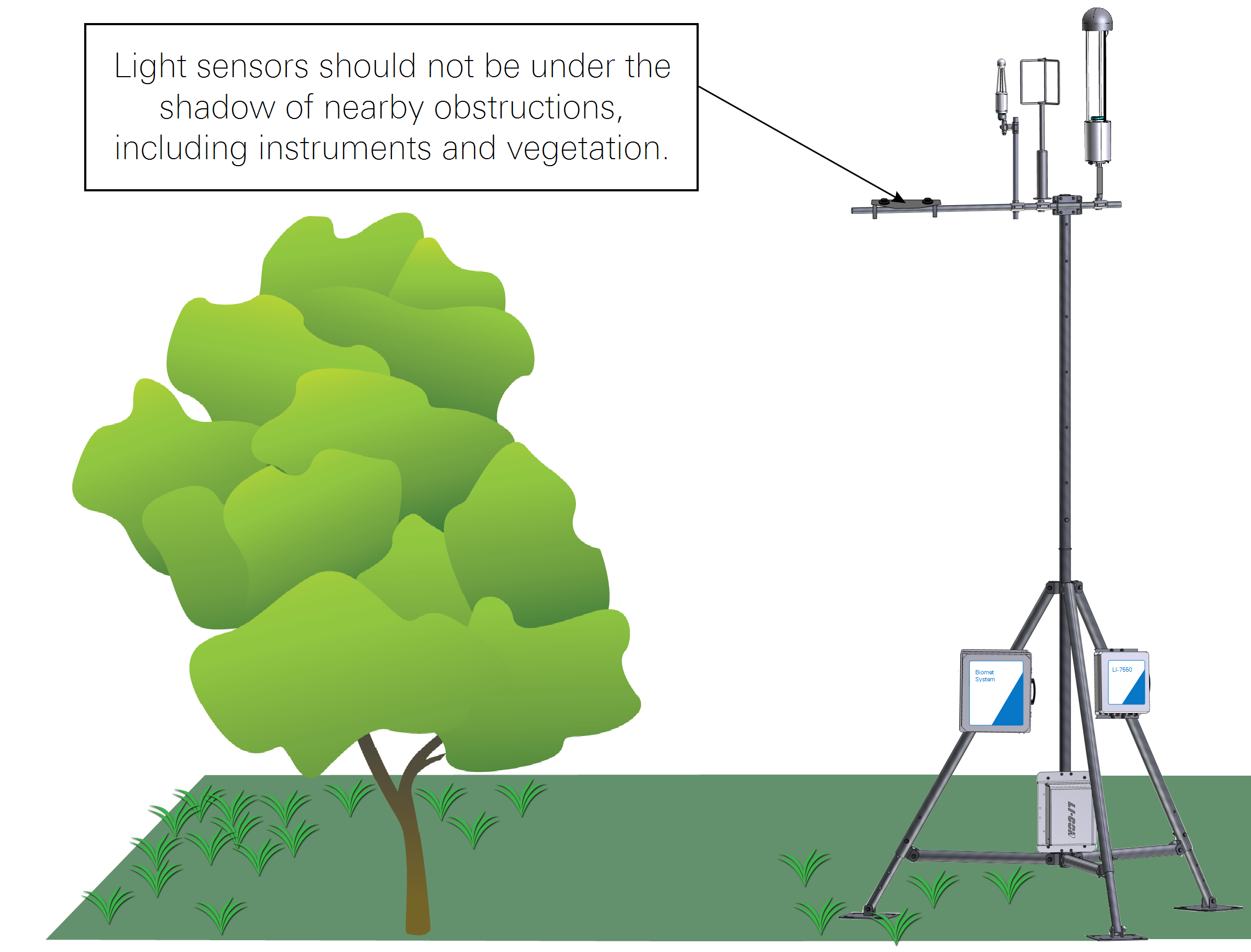

Siting the quantum sensor

Position the LI-190R so it will never be under a shadow, either from the surrounding landscape elements or from the tower itself. Mount the sensor on the tower to minimize reflected radiation that is visible to the sensor.

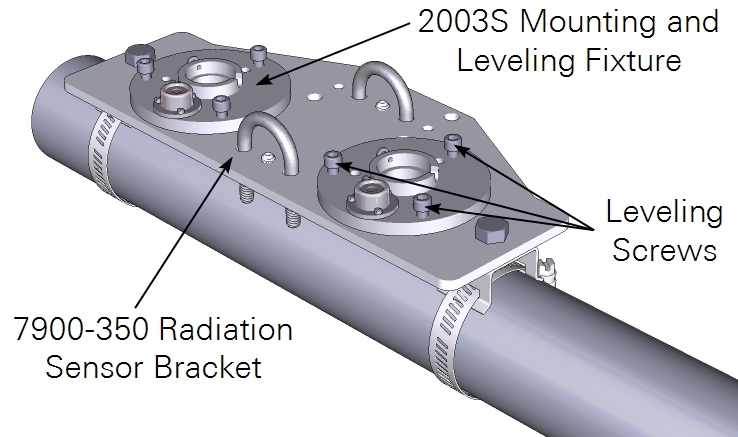

Mounting the quantum sensor

Mount the LI-190R in the mounting and leveling fixture (2003S). Attach the 2003S to the 7900-350 radiation sensor bracket and level the 2003S. Secure the cable to the tower using zip-ties.

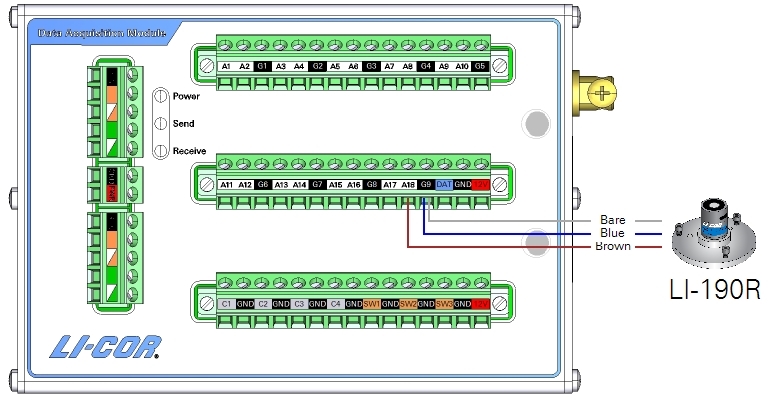

Wiring the quantum sensor

| Description | Wire Color | Terminal |

|---|---|---|

| Signal (-) | Brown | A18 |

| Signal (+) | Blue | G9 |

| Shield | Bare | G9 |

If you want to connect the LI-190R to a channel other than A17 or A18, a millivolt adapter is required.

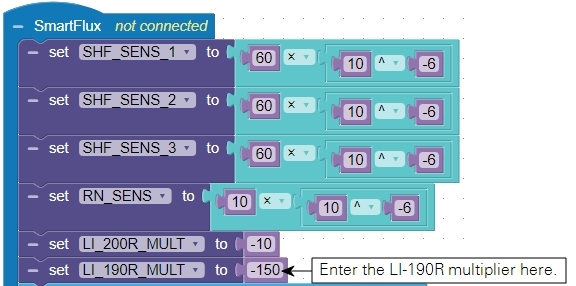

Entering calibration data

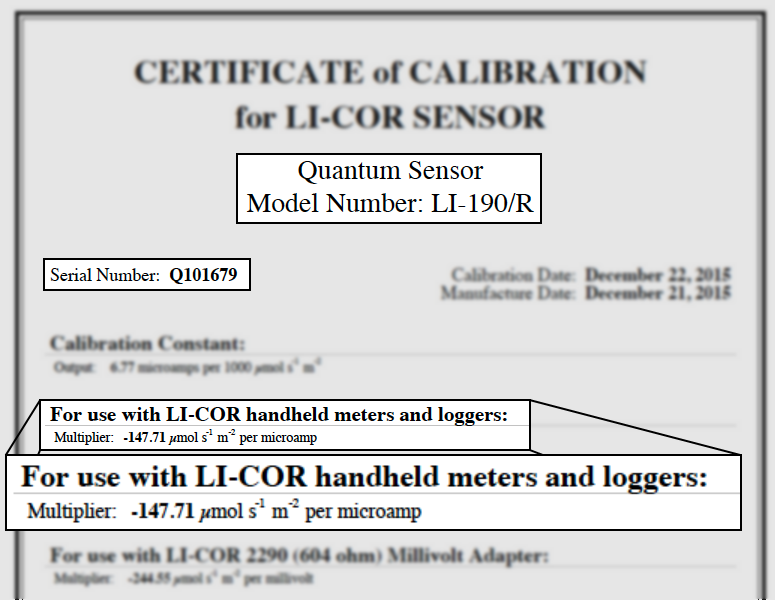

Enter the calibration multiplier in the Blueprint Utility software. The multiplier on the calibration certificate is under For use with LI-COR handheld meters and loggers: (units are µmol photons m-2 s-1 per microamp).

Select a program (Biomet Library) and then enter the calibration multiplier from the calibration sheet.

Save the configuration and push the file to the data acquisition system after entering the remaining calibration information.

Retrieving data

The SmartFlux System will log these data in compressed files for processing by EddyPro Software and evaluation by Tovi Software. Data are stored on the USB drive on the SmartFlux System. Refer to the Data Acquisition System instruction manual for details.

Maintenance

Keep the surface and vertical edge of the acrylic diffuser clean. As needed, clean the diffuser sensor with water, mild detergent, or a diluted vinegar solution using a soft, lint-free cloth. Do not use alcohol, organic solvents, strong detergents, abrasive solvents, or abrasive cloth on the diffuser. Return the sensor to LI-COR for factory recalibration every two years. Contact technical support for more information.