Printable PDF: Constructing a Water Trap For the 7200- 101 Flow Module

This content as a pdf that can be saved to your computer or printed.

The 7200-101 Flow Module is a low power pump designed to work with the LI-7200/RS to achieve flow rates ranging from 10- 18 standard liters per minute. This is accomplished using a blower that helps reduce the power consumption to a nominal 16 Watts at 15 LPM. The LI-7200 comes with a standard 1 meter intake tube, or it can be installed with a custom intake tube. Proper care must be taken when installing the intake tube so that water doesn’t get sucked into the analyzer. The analyzer itself will not be affected by water getting inside the sampling cell, but water pooling inside can lead to data loss for extended periods. As the water dries it can leave hard water stains on the windows that can affect the measurement. The LI-7200 instruction manual (5th printing March, 2013) describes in detail the various ways the intake tube and analyzer can be installed to minimize water intake. Water that gets past the analyzer and gets into the Flow Module can damage the blower motor, so proper installation procedures should be always undertaken to prevent this from happening.

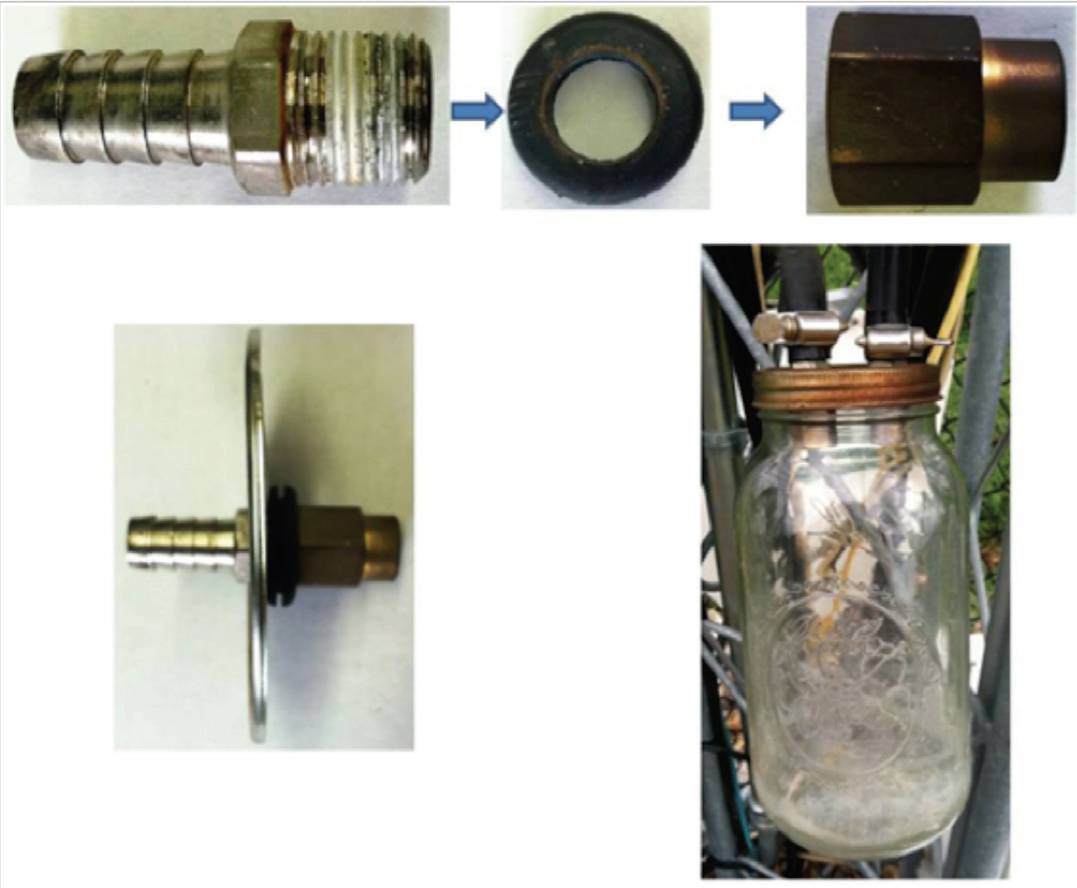

A water trap can be installed in the sampling line to prevent water from getting into the Flow Module blower motor. This type of water trap can be easily constructed using locally available materials. One such water trap construction is illustrated below, which uses a large canning jar. Holes were drilled into the jar lid, so that a 3/8 inch NPT hose barb fitting (LI-COR part # 300-11179) can be inserted. A female NPT 3/8 inch connector is connected to the hose barb fitting with an O-ring of suitable size inserted between the two connectors and the lid of the jar. This ensures that you get a leak-proof connection. Two such connections have to be made. A suitable location to deploy this is just before the air filter (301- 10201) assembly of the Flow Module. The Tygon tubing that connects the sensor head to the Flow Module can be cut just before the air filter to install the water trap, and the connections can be made using hose clamps (300-10788).