LI-7200RS

Enclosed CO2/H2O Analyzer

The next generation of the CO2/H2O gas analyzer chosen by leading flux networks around the world, including NEON and ICOS.

Get a QuoteThe LI-7200RS Enclosed CO2/H2O Gas Analyzer is designed for high-speed CO2 and water vapor gas exchange measurements. It combines the performance of a closed path analyzer with the ruggedness and low power demands of an open path instrument.

Minimizes data gaps with continuous measurements through rain, snow, and fog.

Improved optics and temperature controls increase long-term stability and reduce drift—even when the instrument is not cleaned for weeks at a time.

Logs complete eddy covariance data sets—including wind speed measurements from a sonic anemometer and supporting meteorological, radiation, and soil data from a LI-COR Biomet System.

Now includes the SmartFlux® System

The SmartFlux® System runs EddyPro® Software on a powerful microcomputer to compute final flux results as data are logged—the same dependable results you get from EddyPro Software on a desktop computer, only computed in real time at the site.

SmartFlux is ready to connect with FluxSuite® Software — to put your eddy covariance system online. In FluxSuite, you can view results, get email notifications, and check the performance of your instruments from a computer and smartphone.

The LI-7200RS instrument

Specifically designed for long-term eddy covariance measurements, the LI-7200RS combines the ruggedness of a field–ready instrument with the precision needed for flux measurements.

Patented system of high-speed temperature and pressure measurements of the sampled air provide true mole fraction for the most accurate flux measurements.

Temperature-controlled source and detector for stable measurements—even in wide temperature fluctuations.

Precision optical components reduce sensitivity to contamination in dusty environments.

Scratch-resistant sapphire lenses for simple cleaning in the field.

High-performance brushless chopper motor provides dependable long-term operation.

How it works

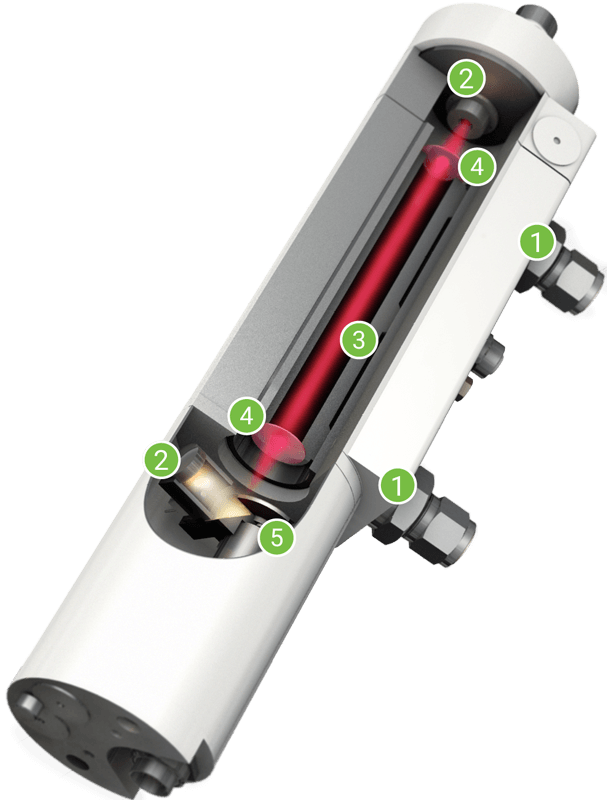

The LI-7200RS uses non-dispersive infrared spectroscopy to measure CO2 and water vapor densities in air. It transmits infrared radiation through temperature-controlled optical filters, then through the closed sample path to a thermally regulated lead selenide detector. Some of the infrared radiation is absorbed by CO2 and water vapor in the sample path. Gas densities are computed from the ratio of absorbed radiation to a reference.

Using a patented configuration, the analyzer also measures temperature and pressure of the sampled air at high speeds—synchronously with the gas measurements. These data are combined to compute wet and dry mole fractions at speeds up to 20 measurements per second.

Components

The following accessories are available for the LI-7200RS.

LI-7550 Analyzer Interface Unit

Included with each LI-7200RS, it houses the gas analyzer electronics, a 16 GB USB drive for data logging, and the SmartFlux System. The LI-7550 has connections for a 3-dimensional sonic anemometer and provides Ethernet communication, making it easy to connect the LI-7200RS with FluxSuite Software.

Inlet Cap

Features an aerodynamic design that minimizes interference with wind flow to maximize frequency response, by minimizing flow distortion and dead volumes. A standard component of the LI-7200RS, the inlet cap is compatible with both the insulated intake tube and optional heated intake tube.

Particle Filter

Two 2-micron Swagelok® particle filters are included with each LI-7200RS. Compatible with both the insulated and heated intake tubes, the filter reduces the need to clean the intake tube and gas analyzer cell, improving the stability of measurements in dusty environments.

Flow Module

Efficient and durable, the Flow Module provides a precisely controlled airflow rate through the LI-7200RS optical path. With precise flow measurements and controls, it actively regulates the flow to ensure stable and consistent airflow rate.

It reports flow rate, pressure drops, and diagnostic data to indicate when filters need to be cleaned or replaced.

Insulated Intake Tube

Included with each LI-7200RS, the insulated intake tube is ideal for measurements in dry environments with low to moderate humidity.

- Compatible with the 2-micron particle filter.

- Minimizes attenuation of CO2 and water vapor, while attenuating temperature by 90% to 99%.

Heated Intake Tube

The optional heated intake tube is recommended for humid environments. It improves frequency response of water vapor measurements by preventing water vapor sorption to the intake tube walls.

- User settable control from 0 to 6 watts.

- Compatible with the 2-micron particle filter.

From the arctic tundra to the arid deserts, the LI-7200RS is designed for the most demanding environments.

Stability and drift resistance

The accumulation of dust, pollen, chemical residues, and other contaminants on the optics of an unfiltered enclosed gas analyzer can lead to measurement drift and cause gaps in datasets. This is not a significant problem if an instrument is filtered and regularly maintained. If an instrument is unfiltered or not maintained, however, there is risk that contaminants will affect measurements.

Innovations in optics and electronics ensure that the LI-7200RS collects more accurate and dependable data—even as contaminants begin to accumulate on the optics.

Data from 13 instruments at 5 sites—with exposure to different levels of contamination—consistently show that the LI-7200RS provides more stable water vapor measurements than the original LI-7200 (Figure 1). CO2 measurements (not shown) are similar to or slightly better than those of the LI-7200.

Click the image to view interactive data (warning: may slow down your browser)

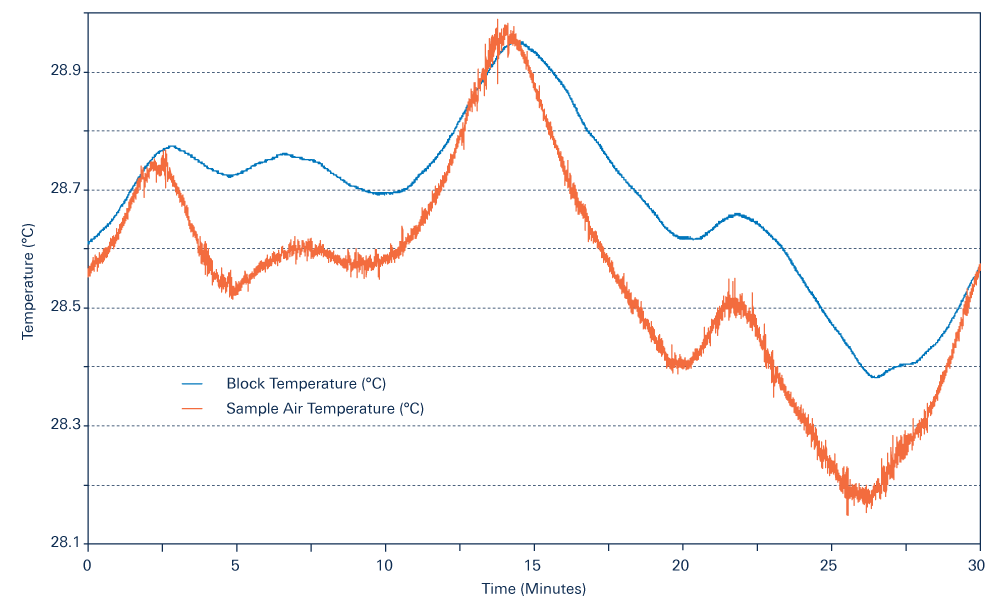

Figure 2. The LI-7200RS measures the sample air temperature and pressure with every gas density measurement. Dampened, low-speed temperature measurements of block temperature will not provide the data required to compute fast mole fractions.

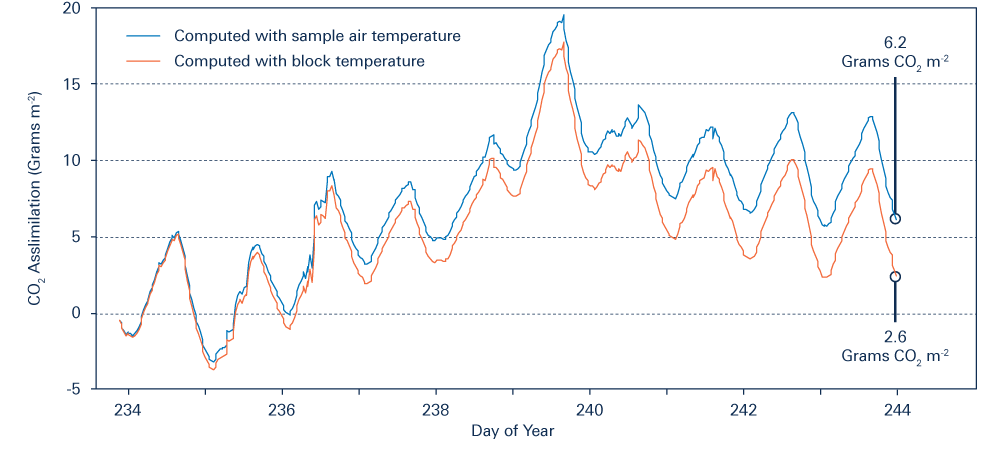

Although the absence of fast air temperature and pressure measurements may appear negligible on half-hourly fluxes, the problems become apparent when computing carbon budgets (Figure 3), which can accrue large differences.

Figure 3. Errors from slow, dampened temperature and pressure measurements, rather than fast measurements of sampled air, accumulate quickly, and become significant after a few days of data collection at this site. By day 10, fluxes were underestimated by 2.4 times.

Specifications

CO2 Measurements

- Calibration Range: 0 to 3000 µmol mol-1

- Accuracy: Within 1% of reading

- Zero Drift (per °C):

- ±0.1 ppm typical

- ±0.3 ppm maximum

- RMS Noise (typical @ 370 ppm CO2 and 10 mmol mol-1 H2O):

- @5 Hz: 0.08 ppm

- @10 Hz: 0.11 ppm

- @20 Hz: 0.16 ppm

- Gain Drift (% of reading per °C @ 370 ppm):

- ±0.02% typical

- ±0.1% maximum

- Direct Sensitivity to H2O (mol CO2/mol H2O):

- ±2.00E-05 typical

- ±4.00E-05 maximum

H2O Measurements

- Calibration Range: 0 to 60 mmol mol-1

- Accuracy: Within 2% of reading

- Zero Drift (per °C):

- ±0.03 mmol mol-1 typical

- ±0.05 mmol mol-1 maximum

- RMS Noise (typical @ 370 ppm CO2 and 10 mmol mol-1 H2O):

- @5 Hz: 0.0034 mmol mol-1

- @10 Hz: 0.0047 mmol mol-1

- @20 Hz: 0.0067 mmol mol-1

- Gain Drift(% of reading per °C @ 20 mmol mol-1):

- ±0.15% typical

- ±0.30% maximum

- Direct Sensitivity to CO2 (mol H2O/mol CO2):

- ±0.02 typical

- ±0.05 maximum

General

- Analysis Type: Absolute, non-dispersive infrared spectroscopy

- Data Storage: 16 GB removable industrial grade USB storage device

- Data Communication: Ethernet, Synchronous Devices for Measurement (SDM; >50 Hz), RS-232 (115,200 baud; 20 records per second max), 6 DACs (0-5 V; 300 Hz)

- Inputs: Four analog input channels (differential; bi-polar; ±5 V; 300 Hz)

- Operating Temperature Range: -25 to 50 °C (-40 to 50 °C verification test available on request)

- Power Requirements: 10.5 to 30 volts DC

- Power Consumption: 12 W nominal (up to 30 W during startup)

- Detector: Thermoelectrically cooled lead selenide

- Bandwidth: 5, 10, or 20 Hz, user-selectable

- User Interface: Windows® based

- Cable length: 5 meters (all cables); 5-meter head cable extension available

Analyzer Head

- Size: 7.5 cm (36” diameter), 31 cm (12.2”) length

- Weight: 1.8 kg (3.95 lbs.)

LI-7550 Analyzer Interface Unit

- Size: 35 cm × 30 cm × 15 cm (13.8” × 12” × 6”)

- Weight: 4.4 kg (10 lbs)

7200-101 Flow Module

- Operating Temperature Range: -25 to 50 °C

- Power Requirements: 10.5 to 30 VDC

- Power Consumption: < 16 W nominal

- Flow Rate: 15 LPM nominal

- Size: 35 cm × 30 cm × 15 cm (13.8” × 12” × 6”)

- Weight: 6.15 kg (13.55 lbs)

Insulated Intake Tube

- Length: Up to 1 meter

- Inside Diameter: 5.33 mm

- Outside Diameter: 6.35 mm

Heated Intake Tube

- Length: 71.1 cm

- Inside Diameter: 5.33 mm

- Outside Diameter: 6.35 mm

- Operating Temperature Range: -40 to 50 °C

- Output Wattage: 0.1 to 6 W

- Heat Density Ratio (short tube to long tube): 2:1

- Weight: 0.54 kg (1.2 lbs)

7550-101 Auxiliary Sensor Interface

- Size: 11.5 cm × 6.5 cm × 4.2 cm (4.5” × 2.6” × 1.7”)

- Weight: 0.39 kg (0.85 lbs) including mounting bracket

Specifications subject to change without notice.

Back to Eddy Covariance Products

Design Your Own System

Continue to learn about customizable eddy covariance systems.